Product Specification

|

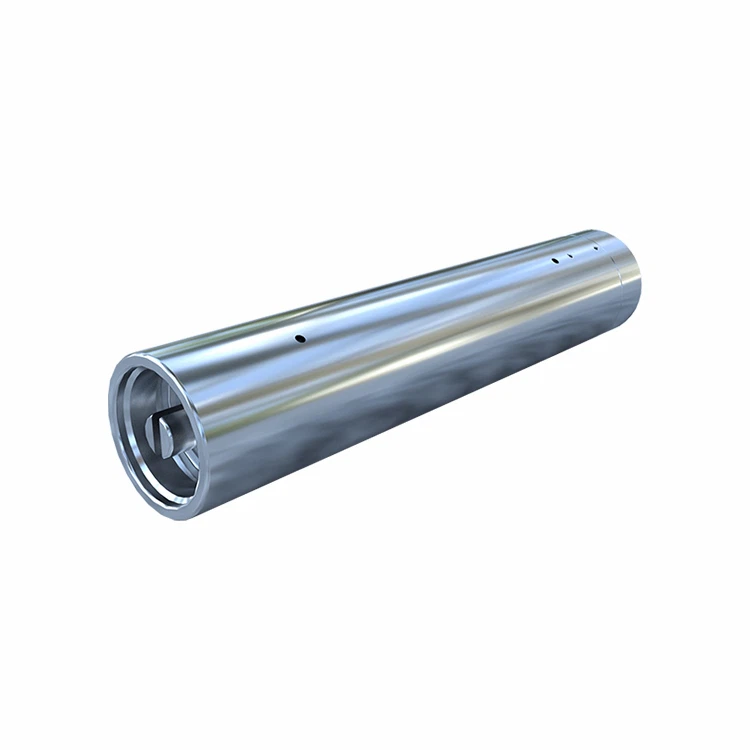

Model |

E201240 |

Heat-resistant temperature |

150-200℃ |

||

|

Rated voltage |

12V |

Rated RPM |

3000 |

Rated torque |

0.012Nm |

|

Rated current |

0.67A |

no-load RPM |

3500 |

Rated efficiency |

62.3% |

|

No-load current |

0.25A |

Rated power |

3.8W |

Interphase resistance |

3.142Ω |

Characteristic

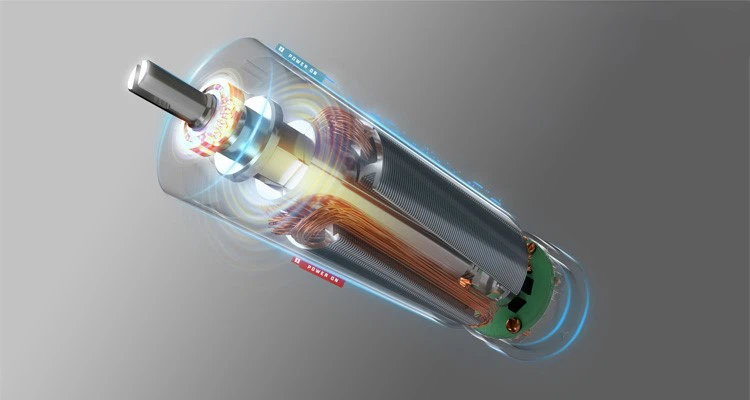

Intelligent integration

Built-in Hall sensor, accurately responding to the speed and position control requirements of downhole tool.

CAN bus or RS485 communication interface can be customized to seamlessly integrate with downhole IoT systems, enabling remote monitoring and fault diagnosis.

Efficient and energy-saving

The brushless design efficiency reaches over 85%, reducing the energy consumption of underground equipment.

Long life maintenance free

Brushless wear reduces maintenance costs and safety risks associated with frequent motor replacement underground.

High power density, micro, meeting the installation needs of small downhole spaces.

High-temp. resistance and strong heat dissipation performance

Adopting high temperature resistant windings (H-class insulation) and ceramic bearings, supporting wide temperature operation from -40 ℃ to +200 ℃, combined with efficient heat dissipation shell design, to avoid performance degradation caused by underground high temperature conditions

Application

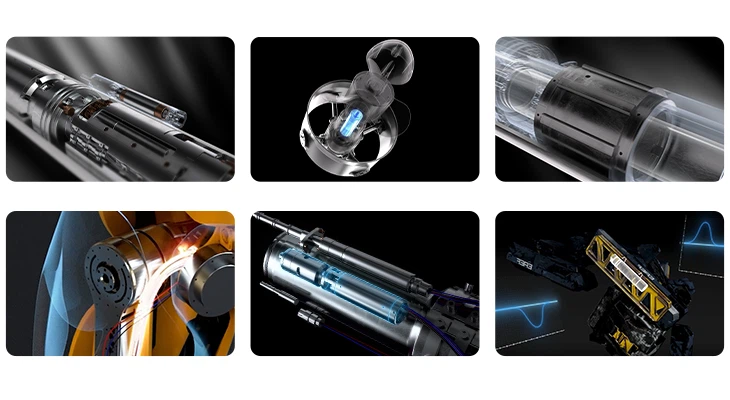

Micro DC brushless motor, resistant to impact and vibration, strengthened mechanical structure, passed military grade vibration and impact testing, suitable for underground drilling.

Normally it is used in intelligent downhole tools for petroleum, micro electronic hydraulic power systems. The precise control and high stability of HELI motor can achieve 0.1% rotational speed accuracy, so also suitable for precision scenarios such as logging instruments.

Besides, due to its micro nature, it is also suitable for high-tech robots, UAG, UAV etc..

As a professional motor manufacturer specializing in the oil field, we have established unique competitiveness in the industry with the following core advantages:

We have own research institute, there is a strong R&D capability and can provide customized services for client.

- We have extreme environmental adaptability technology,

develop specialized sealing structures and anti-corrosion coating technology to ensure stable operation of motors in high-temperature (up to 200 ℃), high humidity (100% RH), and highly corrosive (H2S/CO2) underground environments.

2. Using military grade bearings and special insulation materials, verified through 3000 hours of salt spray testing and 1000 thermal shock cycles

3. Self built precision machining center, with a key component self-made rate of over 90%

The core part of micro DC brushless motor is handmade, with high precision and good quality. The main research areas of Heli Research Institute involve deep earth, deep space, deep sea... Read More

FAQ

Q: Is the motor brushless DC?

A: Yes, it is DC brushless motor

Q: What is the size range of your motor?

A: At present, our standard product outer diameter is 20mm-130mm, but we can customize motor according to client needs, whether it's micro DC brushless motor or other sizes

Q: Where is your production and R&D base located?

A: Tianjin, China.

Q: Can you introduce some clients who are currently using your product?

A: Our clients are mostly oilfield equipment companies and robotics companies from Europe, the Middle East, Southeast Asia, etc. For specific names, please contact the sales manager

Q: How efficient are Mirco DC brushless motor?

A: Brushless motors have higher efficiency rates of up to 85 to 90. This means that the mechanical power of a BLDC motor can be up to 90% of the total electrical power input.

Hot Tags: micro dc brushless motor, China micro dc brushless motor manufacturers, suppliers, dc brushless motor, drilling tool, High Pressure Axial Oil Pump, High Temperature Oil Pump, High Stability Drilling Motor, 20mm Diameter Oil Pump